AI-Powered Virtual Validation

Garments Virtual Validation Redefining Smart Factory Prototyping with AI

Introduction

In the competitive field of garment manufacturing, the connection between a digital design and a physical product often results in waste. Traditionally, smart factories used physical samples to test how a garment fits different body types. This process is slow, costly, and harmful to the environment.

This case study focuses on the AI Virtual Try-On (VTO) feature, a cornerstone of digital transformation that allows factories to instantly verify designs instantly using a vast AI Model Library and Custom Photo Integration.

The Problem

The Prototype Trap

Smart factories and fashion brands face critical inefficiencies during the design validation phase

The "One-Size" Fallacy

Physical samples are typically made for a single "fit model" size, leaving manufacturers guessing how the design scales across diverse body types.

Prototyping Waste

Every design iteration requires a new physical sample, contributing to the 40-60% of pre-production waste in the industry.

Lead Time Bottlenecks

Waiting for physical samples to be sewn, shipped, and reviewed can delay production by weeks.

High Costs

Each physical prototype costs significantly more than a mass-produced unit due to manual labor and setup.

The Cumulative Impact

These inefficiencies compound throughout the design-to-delivery pipeline, resulting in extended time-to-market, inflated costs, environmental damage, and limited ability to serve diverse customer bases. Smart factories need a radical shift from physical-first to digital-first validation.

The Solution

AI Virtual Try-On (VTO)

Eliminate the need for early-stage physical samples by providing high-fidelity digital previews of garments on any body type, instantly

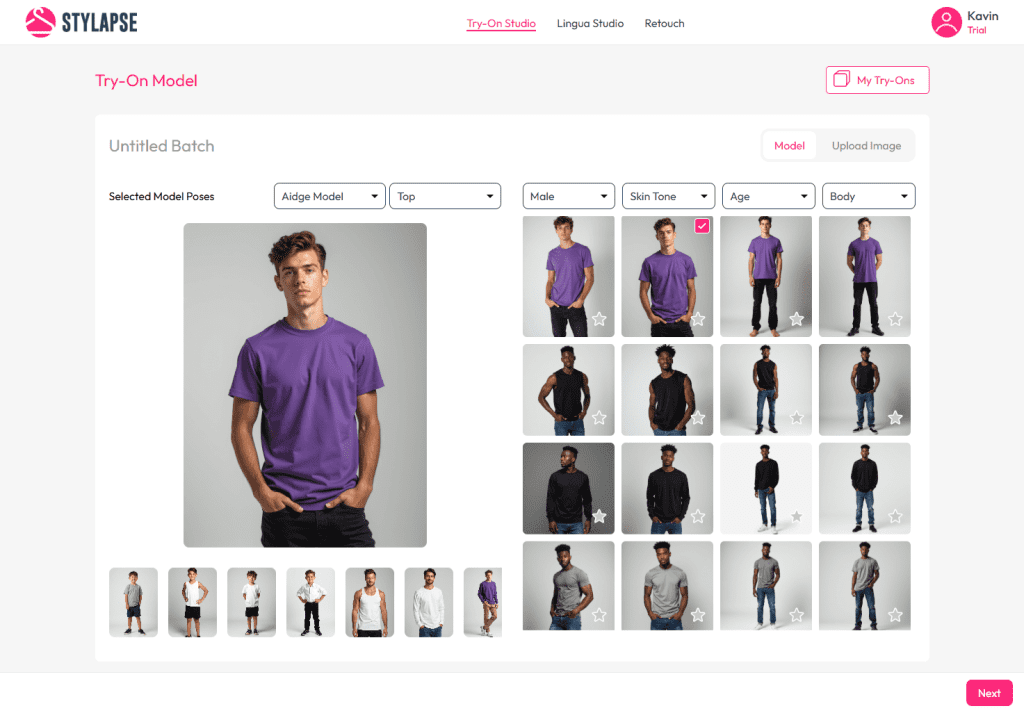

Comprehensive AI Model Library

Access an extensive library of AI-generated models instead of hiring diverse casting for fit testing

- All ages, skin tones & body types

- Petite to plus-size representation

- Realistic human poses & movement

Custom Photo Integration

Upload specific photos of real individuals to see 1:1 digital drape on actual fit models or market influencers

- Upload any photo format

- Precise body mapping

- Instant rendering results

Batch Garment Previews

Process entire collections simultaneously instead of one-by-one rendering for maximum efficiency

- Upload multiple garment flats

- Render across 100s of models

- Compare variations instantly

How It Works

Select Models

Choose from AI Model Library or upload custom photos

Upload Design

Import garment flats, tech packs, or 3D models into the platform

AI Processing

Advanced algorithms render realistic garment draping and fit

Review & Validate

Analyze fit across body types and approve for production

Digital-First Validation

The AI Virtual Try-On feature represents a fundamental shift from physical- first to digital-first validation. By leveraging advanced machine learning and computer vision, manufacturers can confidently approve designs before investing in physical samples.

The Impact

60% Faster Design-to-Delivery

By shifting validation to the digital realm, smart factories have achieved significant operational wins across all key metrics

60%

Faster Time-to-Market

Accelerated design validation eliminates weeks from production timeline

40-60%

Prototype Reduction

Virtual validation catches issues before physical sampling

$1000s

Cost Savings Per Collection

Eliminated sample runs and casting logistics dramatically reduce costs

85%

Carbon Footprint Reduction

Lower fabric waste and reduced international shipping

Before AI Virtual Try-On

12-23 days per iteration

Sample creation, shipping, and review cycles

5-8 physical samples per design

Multiple iterations for fit validation

Limited body type coverage

Only 12% of diversity represented

$150-500 per sample

High manual labor and setup costs

40-60% pre-production waste

Discarded samples and fabric scraps

After AI Virtual Try-On

2-5 seconds per render

Instant digital validation across all body types

1-2 physical samples (final only)

Confirmed designs before physical production

1,000+ diverse AI models

Complete body type, age, and pose coverage

$0.50-2 per render

Fraction of physical sample costs

85% waste reduction

Minimal physical sampling required

Conclusion

The Ultimate Validation Tool

The AI Virtual Try-On feature is the ultimate validation tool for the modern smart factory. By combining the flexibility of a diverse AI Model Library with the precision of Custom Photo previews, manufacturers can confidently greenlight production with a “digital first” mindset.

No More Photoshoots

With lifelike AI-generated models, brands can now showcase clothing on realistic virtual humans that reflect diverse body types, skin tones, and styles without the cost or complexity of traditional photography.

This revolutionary approach eliminates numerous logistical challenges:

- No more scheduling conflicts with human models

- Instant ability to showcase on different body types

- Elimination of studio rental and equipment costs

- 24/7 production capability without human fatigue

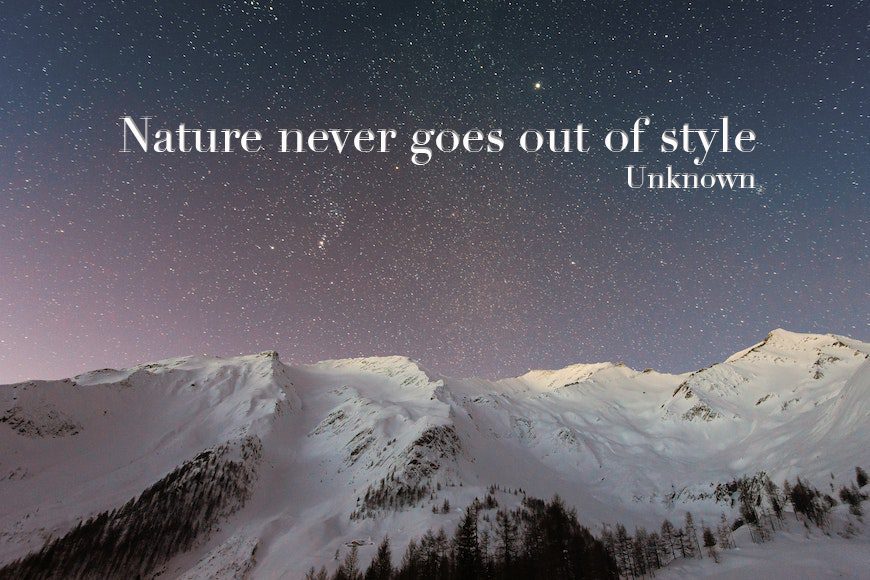

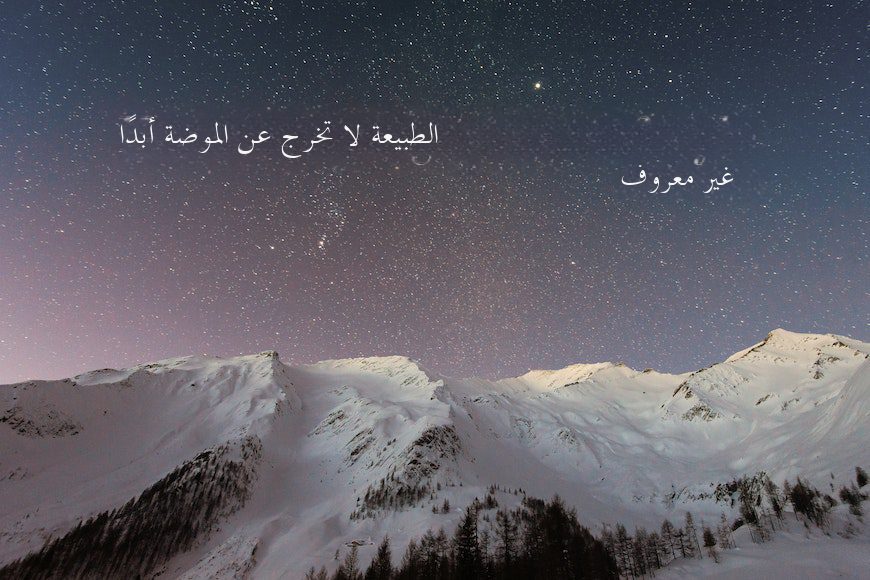

Speak Every Customer's Language

Our AI tool can translate both text and visual content for global rollouts, ensuring your product labels, ads, and storefronts are always localized. This isn't just about translating words it's about maintaining brand consistency across cultures.

The platform handles everything from:

- Product description localization with industry-specific terminology

- Visual text translation on labels, tags, and packaging

- Cultural adaptation of visuals for different markets

- Automatic sizing conversion between regional standards

Professional Image Editing, Automated

AI auto-enhances photos by adjusting lighting, removing flaws, and applying brand-consistent filters, so your visuals are always on point without human effort.

The system handles complex retouching tasks automatically:

- Background removal and replacement

- Color correction and consistency across product lines

- Shadow and highlight optimization

- Fabric texture enhancement

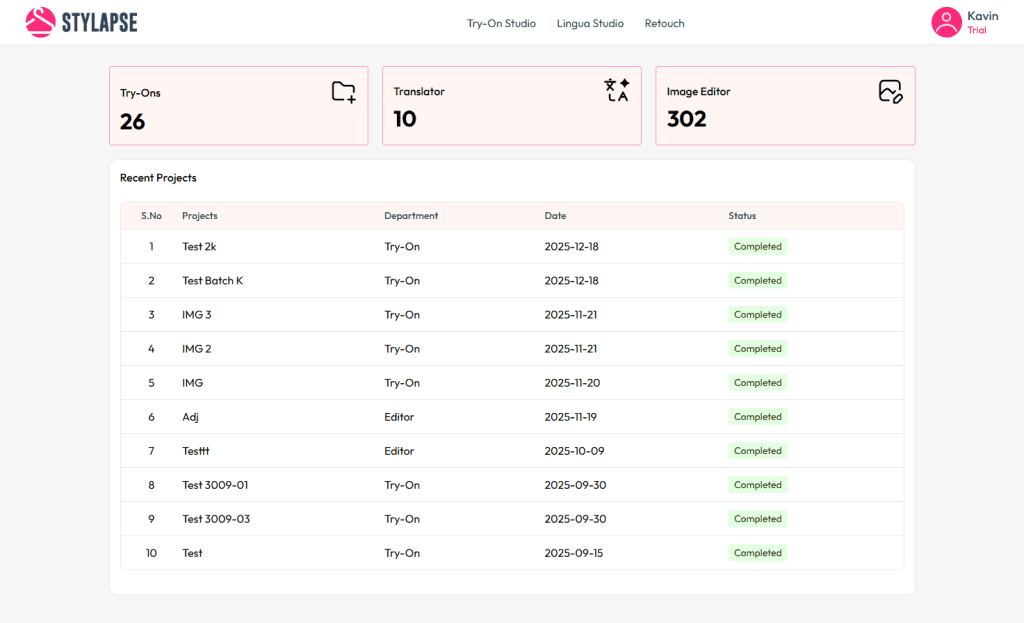

Centralized Dashboard

Our AI-powered dashboard is designed to give you complete visibility and control over your data operations. At a glance, you can see how many batches are being processed, and detailed stats on completion rates.

The dashboard provides comprehensive insights:

- Real-time monitoring of batch processing

- Historical performance data and trend analysis

- Team collaboration tools and approval workflows

- Resource allocation and optimization recommendations

Reimagine Fashion with AI From Concept to Visuals

All-in-one intelligent platform to design, model, translate, and refine fashion collections at scale. Our solution is crafted to increase creative output while cutting production time by up to 60%.